Grade-separation challenges? A design-build approach can assist you in matching the best wall/slope reinforcement options to solve your problem. Normally one wall type isn’t the solution to every problem so having multiple custom designed options can provide optimum results.

GeoStructures’ provides Design-Supply-Build options for the following retaining wall and wall combinations:

Customers receive various design-build services when utilizing these multiple systems. These services consist of engineering, cost feasibility, firm fixed pricing for construction which includes details for project aesthetics, scheduling and alternatives in order to beat the budget.

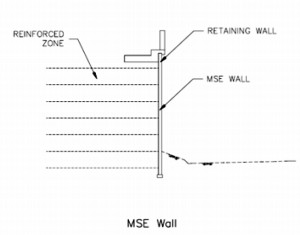

MECHANICALLY STABILIZED EARTH (MSE) WALLS

MSE walls offer the most flexible, aesthetic and economical wall system when retaining walls are required in a fill condition or if there is enough lay back to make a cut approximately equal to the wall height. MSE walls consist of a well compacted granular backfill that can be reinforced with ribbed steel strips, geogrid or geosynthetic strip reinforcement. Reinforcements are attached to a concrete or wire facing to form a coherent gravity mass that is internally stable. Reinforcement lengths are designed to be long enough to create a mass that is big enough to resist sliding, overturning and bearing failures.

Among the benefits of MSE are:

■ Cost Savings – Usually 20 – 40 percent less than conventional cast-in-place concrete walls

■ Quick Installation – Speed is as fast as the rate of placement and compaction of backfill

■ Aesthetics – Wire facings, precast concrete panels with form finishes and stains

■ Flexible – MSE Walls can tolerate total settlement of up to 12 inches and differential settlement of 1% in 100 feet

GEOSYNTHETIC REINFORCED SOIL WALLS

The use of Geosynthetic strips or Geogrid for soil reinforcing elements can provide cost savings based on the use of alternate backfill materials. MSE Walls that utilize galvanized steel require specific stone backfill which meet tight resistivity and sulfate and chloride limits. Backfill requirements for geosynthetics are less stringent with limitations in terms of backfill pH, so saline soils can normally be used with geosynthetics.

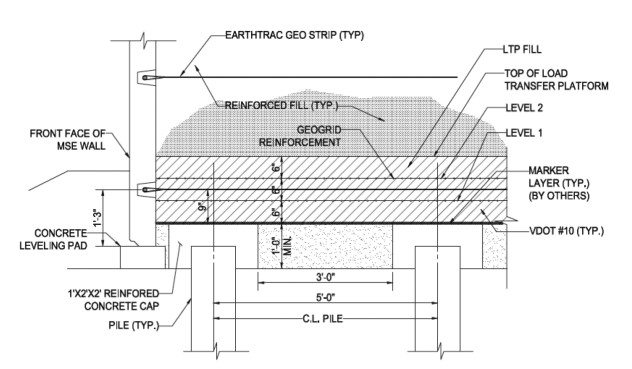

Use of Geosynthetic GeoStrip Reinforcements and Sand Backfill

Typical Detail of a Pile Supported Load Transfer Platform and a GeoStrip Reinforced Soil MSE Wall

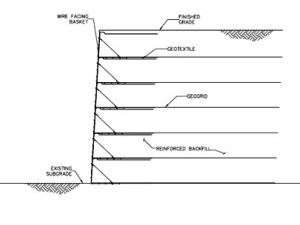

WIRE - FACED MSE WALLS

The use of wire faced MSE walls with a geosynthetic strip or Geogrid reinforcements allows for alternate fills to be used and provides alternate facing options. Typically a vegetated or rock filled facing is used. The benefits of these walls are they provide a lower cost alternative for walls where aesthetics is less of a concern or where a green look is desired.

55 foot tall wire faced wall for a site development project; Wall was supporting a roadway and faced the forest

WIRE - FACED PRESSURE RELIEF MSE WALLS

Wire Faced walls can be used to eliminate lateral earth pressure on below grade walls. Walls are normally built with a 6 to 10 inch space between the face of the wire wall and the back of the below grade wall. The void is spanned at the top of the wall. In this way the below grade wall can be designed for compression loads only. The benefit is the use of a less expensive structural wall (often masonry block) which does not need to be designed for lateral earth pressures.

UVA John Paul Jones Arena, Charlottesville, Virginia

40 foot high pressure relief wire faced MSE Wall

Geogrid Reinforcement and granular backfill

10” spacing between wire wall face and arena wall

POST-AND-PANEL (H-PILE) WALLS

For grade separation in a cut condition, post-and-panel (P&P) walls provide a quick, economical and aesthetic solution. Benefits include:

■ Ability to build closer to Temporary & Permanent Easements – P&P walls can be placed within feet of the property line and only require a few feet of access for final backfilling.

■ Minimizes Cuts and Fills – Small footprint means no over-cutting of soil required.

■ Aesthetics – Facings vary from treated timbers to precast concrete panels with form finishes and stains. Posts can be galvanized H-piles, or concrete posts.

■ Avoid Utility Conflicts – With post spacing on the order of 8 to 10 feet on center, drilled shafts can be placed to avoid existing utilities and adequate space for new utilities can be provided.

Post and Panel site wall at US Post Office Annex, Alexandria, Virginia

Plain concrete panels and galvanized steel posts with brick columns and fencing on top.

Post and Panel and Segmental Retaining Wall, Reston, Virginia

Tan stain used on Post and Panel wall to match split faced block walls built on the property line to maximize parking spaces

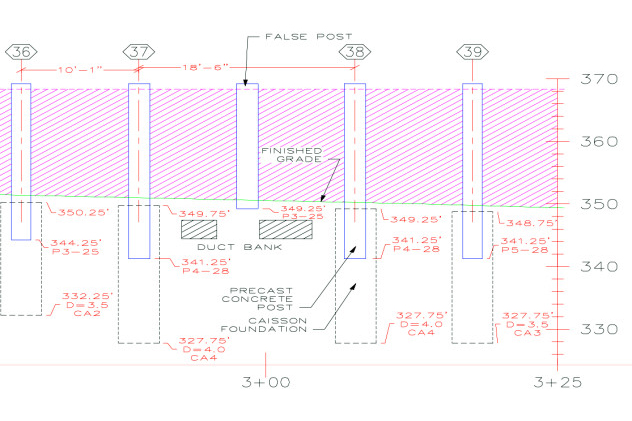

Concrete Post and Panel wall up to 22 foot tall used to replace CIP concrete wall.

False Post used to Span Large Existing Utility Duct Bank.

STEEPENED SLOPES IN FILL AND CUT SLOPE APPLICATIONS

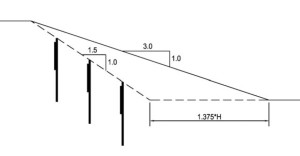

Steepening an earth slope beyond the slope angle at which the shear strength of the soil can safely hold it in place (normally 2(H):1(V) to 3(H):1(V) slopes) requires the use of some type of soil reinforcement and erosion control or facing system.

FILL SLOPES

For fill slopes geogrid reinforcing elements have been used to build slopes as steep as 1(H):1(V) using conventional earth moving equipment and erosion control matting as well as steeper up to vertical walls using a wire basket facing.

CUT SLOPES

The Geopier SRT™ system, which utilizes Plate Pile™ technology, can be used to reinforce soils in place to assure adequate slope stability for steep slope applications such as:

■ New or existing Embankments Adjacent to or under Bridge Abutments

■ Creating more Usable areas for Building sites

■ Temporary Shoring